Waterproof Adapters: Essential Features for Outdoor and Industrial Use

A waterproof adapter may look simple from the outside, but in practice, it often plays the role of an unsung guardian—keeping power stable, sealing off moisture, and preventing downtime that could cost a business real money. Over the past decade, as industries shifted toward more distributed equipment setups and outdoor electronics became standard, waterproof power and data adapters evolved from nice-to-have accessories into critical infrastructure.

What often gets overlooked is that not all waterproof adapters are built to the same standard. A connector rated for garden lighting won't survive in a marine engine room, and a device used for solar street lights won't necessarily be compatible with industrial automation networks. Understanding what separates a reliable waterproof adapter from a weak one has become increasingly important for OEM manufacturers, electrical engineers, and even consumers who are expanding their smart-home systems outdoors.

Why Waterproofing Matters More Than Ever?

Waterproof adapters aren't just about keeping rain out. They serve as protection against humidity, condensation, salt spray, corrosive dust, high-pressure washdowns, and even immersion. As outdoor LED lighting, surveillance cameras, EV chargers, and IoT sensors proliferate, the level of protection required has gone up. Today, many equipment designers prioritize IP67 connectors, IP68 waterproof adapters, and even IP69K-rated connectors for harsh washdown environments in food-processing plants.

Outdoor connectivity also needs to withstand freeze-thaw cycles. Anyone who has worked with equipment in northern climates knows that temperature swings create micro-cracks in cheap plastic housings. Over time, those cracks pull moisture inside the connector body—right where you don't want it. Quality waterproof adapters use materials like nylon, PA66, TPU, or rubberized overmolding to absorb expansion stress and prevent water ingress.

Because of this, industries such as industrial automation, solar power systems, AGV robotics, marine electronics, and smart city infrastructure rely heavily on weatherproof connectors and waterproof cable assemblies that won't fail after a few seasons.

Key Features to Look for in Waterproof Adapters

Instead of reading a generic spec sheet, it's helpful to understand why certain features matter. Below are the characteristics that truly separate robust waterproof adapters from low-tier ones.

1. A Meaningful IP Rating (Not Just Marketing Copy)

You'll see IP ratings on nearly every waterproof connector, but many people misunderstand what the numbers represent. For example:

● IP65 handles dust and low-pressure water jets.

● IP67 means temporary immersion for up to 1 meter.

● IP68 varies by manufacturer but typically covers long-term or deeper immersion.

● IP69K stands up to extremely high-pressure, high-temperature washdowns.

A good manufacturer will publish actual test conditions, not just the rating. When evaluating products, look for waterproof adapters that clearly list the immersion time, depth, or water pressure used during testing. Brands that build connectors for telecom towers or marine equipment usually provide this information because they design for mission-critical use.

2. Rugged Housing Materials

Most people think plastic is plastic, but for adapters, material selection determines lifespan. High-quality waterproof connectors usually rely on:

● PA66 nylon for mechanical stability

● PC (polycarbonate) for impact resistance

● TPU rubber overmolding for flexible strain relief

● Stainless steel or brass shells for industrial M12 connectors and marine systems

● UV-resistant coatings for outdoor solar installations

If the adapter will be exposed to direct sun, saltwater, oil, or chemicals, the housing material matters as much as the sealing grade. For example, waterproof DC connectors used in outdoor LED drivers often fail because of UV-degradation, not water itself.

3. Secure Locking Mechanisms

In outdoor or mobile environments, vibration is constant. A loose connector is more dangerous than a non-waterproof one. For this reason, many industrial users rely on:

● Threaded locking rings for M8/M12 connectors

● Push-pull locking for easy tool-free installation

● Bayonet locking for quick-release field connections

● Twist-lock AC power adapters for marine and camping power systems

The type of locking mechanism also affects waterproofing. A threaded waterproof adapter, for example, compresses the internal gasket more uniformly than a friction-fit connector.

4. Internal Sealing: O-Rings, Gaskets, and Potting

The external casing gets most of the attention, but the internal sealing makes or breaks long-term durability. Look for features like:

● Silicone O-rings around entry points

● Rubber gasket compression around the mating surface

● Gel-filled or epoxy-potted interiors for permanent installations

● Double-sealed cable glands for cable strain relief

If you see a waterproof adapter with no visible gasket or gland, that's usually a red flag.

5. Tolerance for Temperature and Chemical Exposure

Applications like chemical plants, agricultural systems, and fuel stations introduce challenges far beyond simple moisture. Waterproof adapters may need:

● Corrosion-resistant metal shells

● High-temperature silicone seals

● Oil-resistant TPU cable jackets

● Wide operating temperature ranges (–40°C to 85°C or more)

For industrial automation, M12 waterproof adapters paired with PUR-jacketed cables are common because PUR resists oils and vibration better than PVC.

6. Compatibility and Connector Types

A great waterproof seal means nothing if the adapter doesn't match your system. Common connector formats include:

● Waterproof USB connectors for field diagnostics and data transfer

● Waterproof RJ45 Ethernet connectors for outdoor IP cameras and routers

● DC waterproof plugs and jacks for LED power lines

● M8/M12 circular connectors for sensors, robotics, and PLC systems

● Waterproof AC power adapters for marine and camping equipment

OEMs often work with connector manufacturers who can provide custom pin configurations, molded cable lengths, and matched waterproof cable assemblies.

Industrial and Outdoor Applications Where Waterproof Adapters Excel

A surprising number of industries now depend heavily on waterproof adapters—not because they want to, but because outdoor electronics have become part of the job.

Outdoor LED Lighting and Solar Systems: Street lights, landscape lighting, solar garden lights, and billboard displays all rely on stable low-voltage power. Waterproof DC adapters and IP67 LED power connectors ensure that rain or irrigation systems don't cause outages.

Smart Cities and Surveillance Systems: Modern cities use thousands of outdoor IP cameras, Wi-Fi hotspots, EV charging stations, and traffic sensors. These networks typically use waterproof Ethernet connectors, UV-resistant housings, and secure locking systems to keep data flowing under all weather conditions.

Marine and Offshore Equipment: Saltwater is brutal on electronics. Waterproof adapters designed for boats, docks, and offshore platforms often use:

● Nickel-plated brass connectors

● Corrosion-proof rubber seals

● High-amp waterproof AC power connectors

● Shock-resistant housings

This is one area where cheap connectors fail almost immediately.

Factory Automation and AGVs: Factories with washdown procedures, conveyor belts, and autonomous robots cannot risk water entering control systems. M12 waterproof connectors, coded for specific data or power types, handle vibration and frequent cleaning far better than consumer-grade products.

Agriculture and Irrigation Control: Irrigation systems expose connectors to water, fertilizer chemicals, uneven ground, and heat. A waterproof adapter with a strong cable gland and dust-resistant seal is essential to prevent corrosion and electrical shorts.

Working With a Reliable Manufacturer Matters

Even with high IP ratings and rugged designs, the quality of a waterproof adapter often comes down to manufacturing precision. Many OEM equipment builders partner with connector manufacturers who specialize in waterproof power and data solutions. These companies offer:

● Customized waterproof cable assemblies

● Molded connectors for unique pinouts

● Long-term supply for large-volume manufacturing

● Strict QC testing with real immersion tests

● Certification support (UL, CE, RoHS)

Choosing a supplier who understands your application is far more valuable than choosing the cheapest product on a search page.

Conclusion

Waterproof adapters may look like ordinary components, but in outdoor and industrial environments, they act as the protective barrier that keeps equipment running day after day. From rugged IP68 connectors used in marine systems to compact waterproof USB connectors used in field diagnostics, these components must withstand moisture, vibration, chemicals, and temperature extremes. Understanding the essential features—durable materials, reliable locking mechanisms, sealing structures, and meaningful IP ratings—helps ensure long-term system stability.

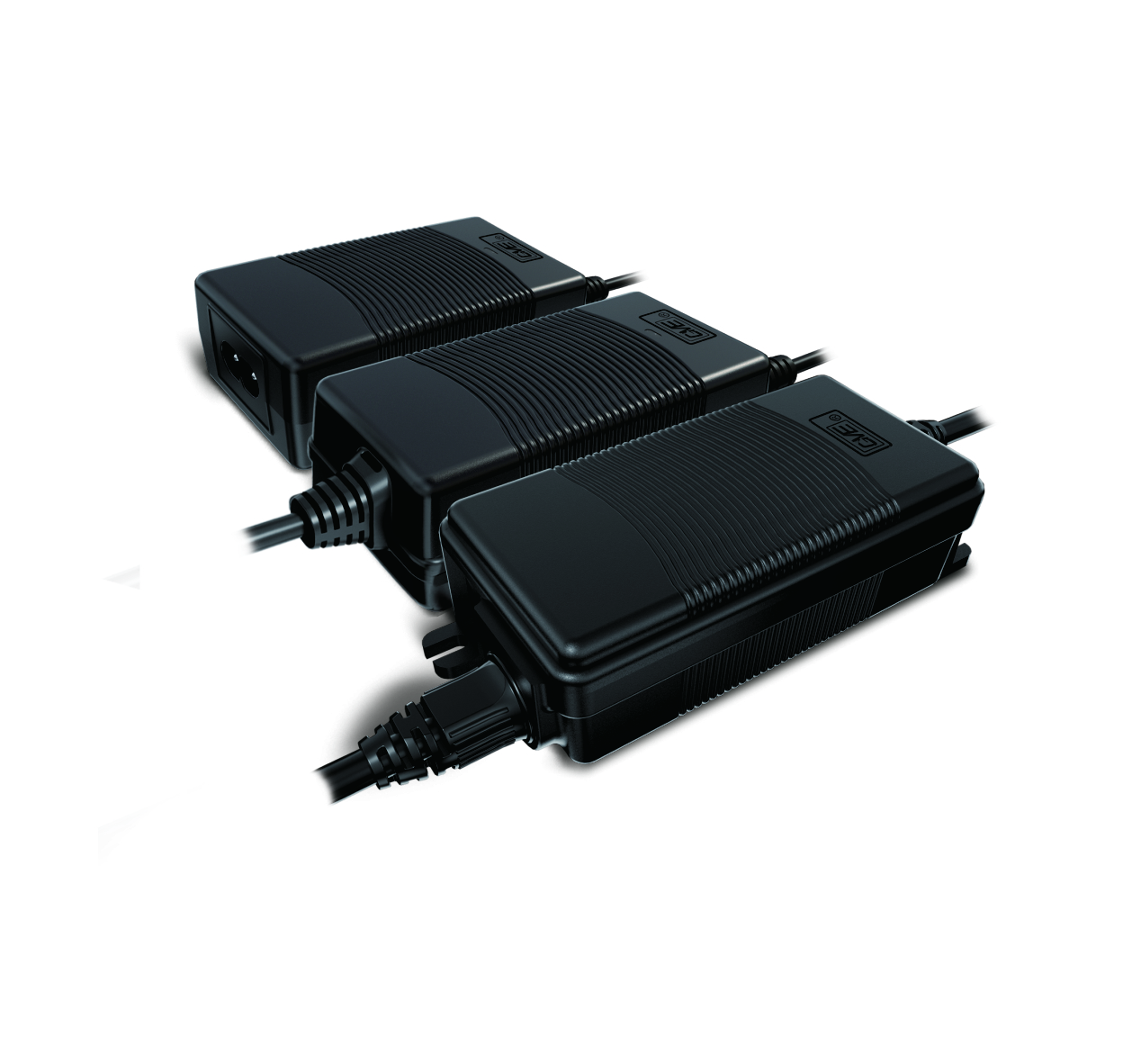

For businesses developing outdoor electronics or industrial systems, partnering with a professional manufacturer is just as important as selecting the right specifications. If your project requires dependable waterproof adapters built for real-world conditions, choosing a supplier like GVE can make a measurable difference in durability, safety, and system uptime.